Smarter solutions for demanding dragline operations

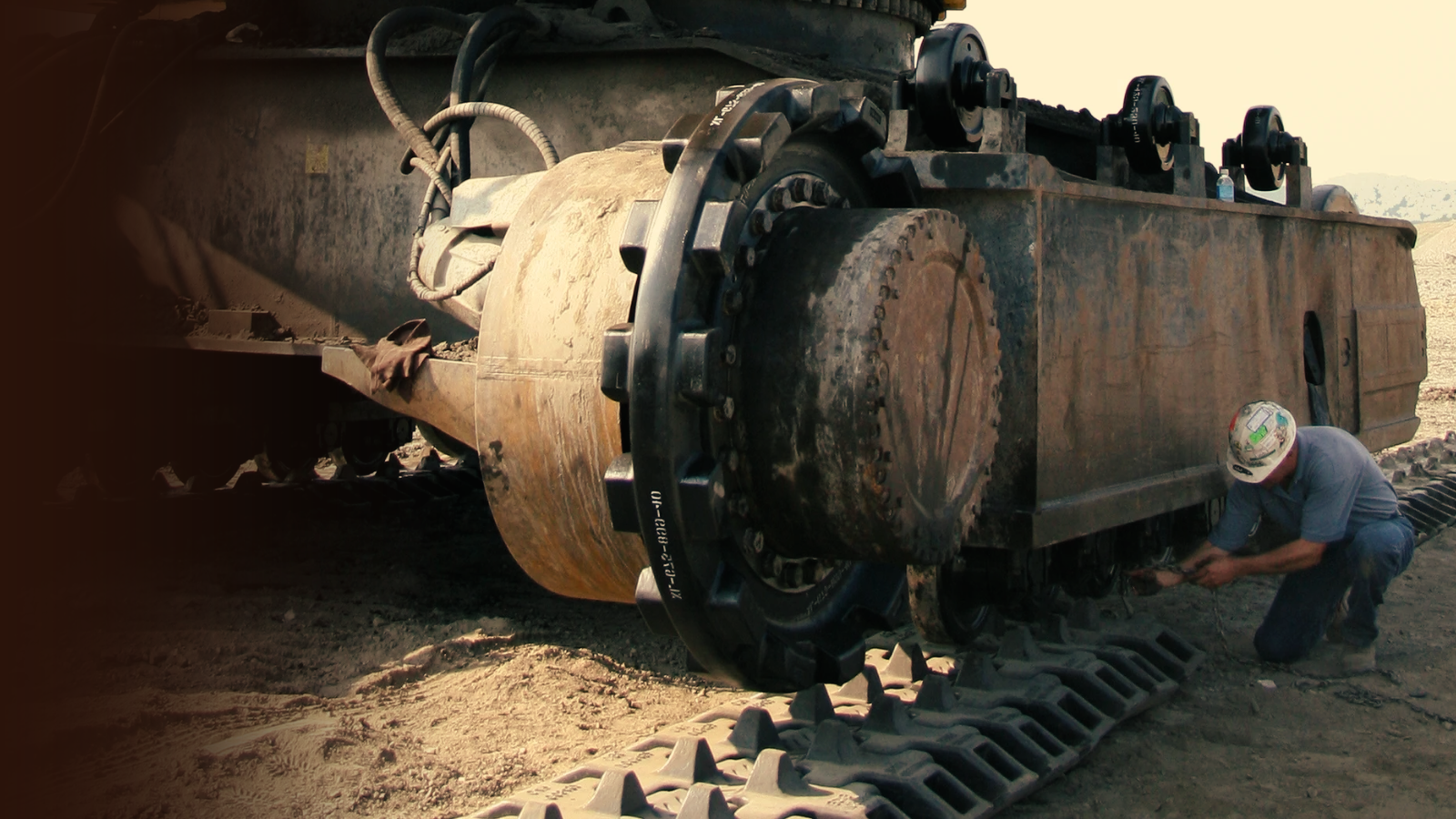

Draglines are among the most critical machines in mining—and downtime is costly. Excel™ parts go beyond replacement by solving common maintenance challenges. From hoist drums and swing components to undercarriage parts, every product is built for durability, precise fit, and reliable performance in the toughest conditions.