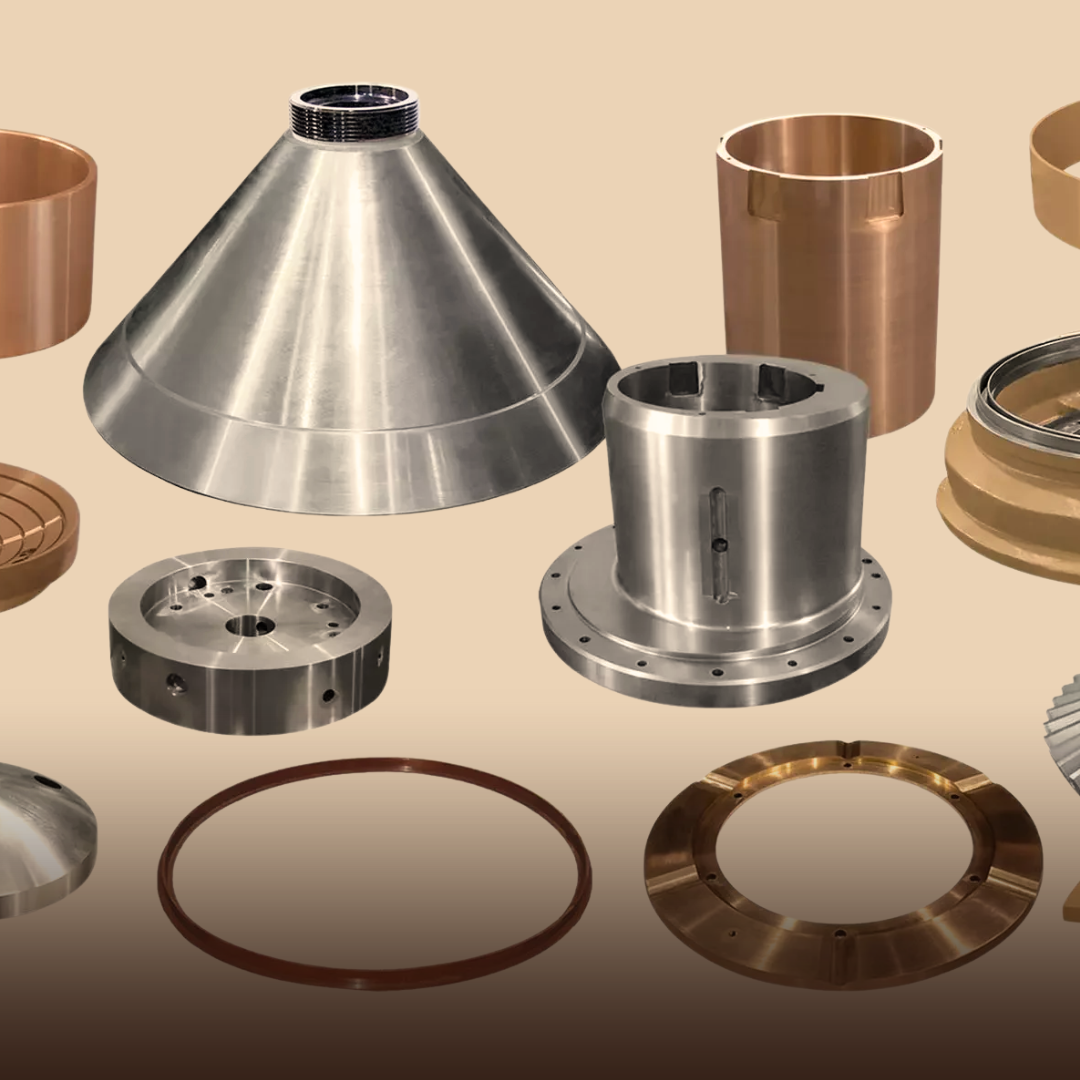

Beyond Parts: Lasting solutions for mining and aggregates

In mining and aggregates, you need durable, top-quality spare parts that get your machines back up and running fast. But we don’t stop there. At Excel, we work closely with customers to identify recurring challenges and deliver smarter solutions — from optimizing crusher wear life to reducing unplanned downtime. Our goal is not just to supply parts, but to help you overcome problems and keep production moving.